Ningbo Xinda Screw Compressor Co., Ltd.

NINGBO XINDA SCREW COMPRESSOR CO., LTD

Founded in1998

Committed to continuous product optimization and improvement.

查看详情NINGBO XINDA SCREW COMPRESSOR CO., LTD

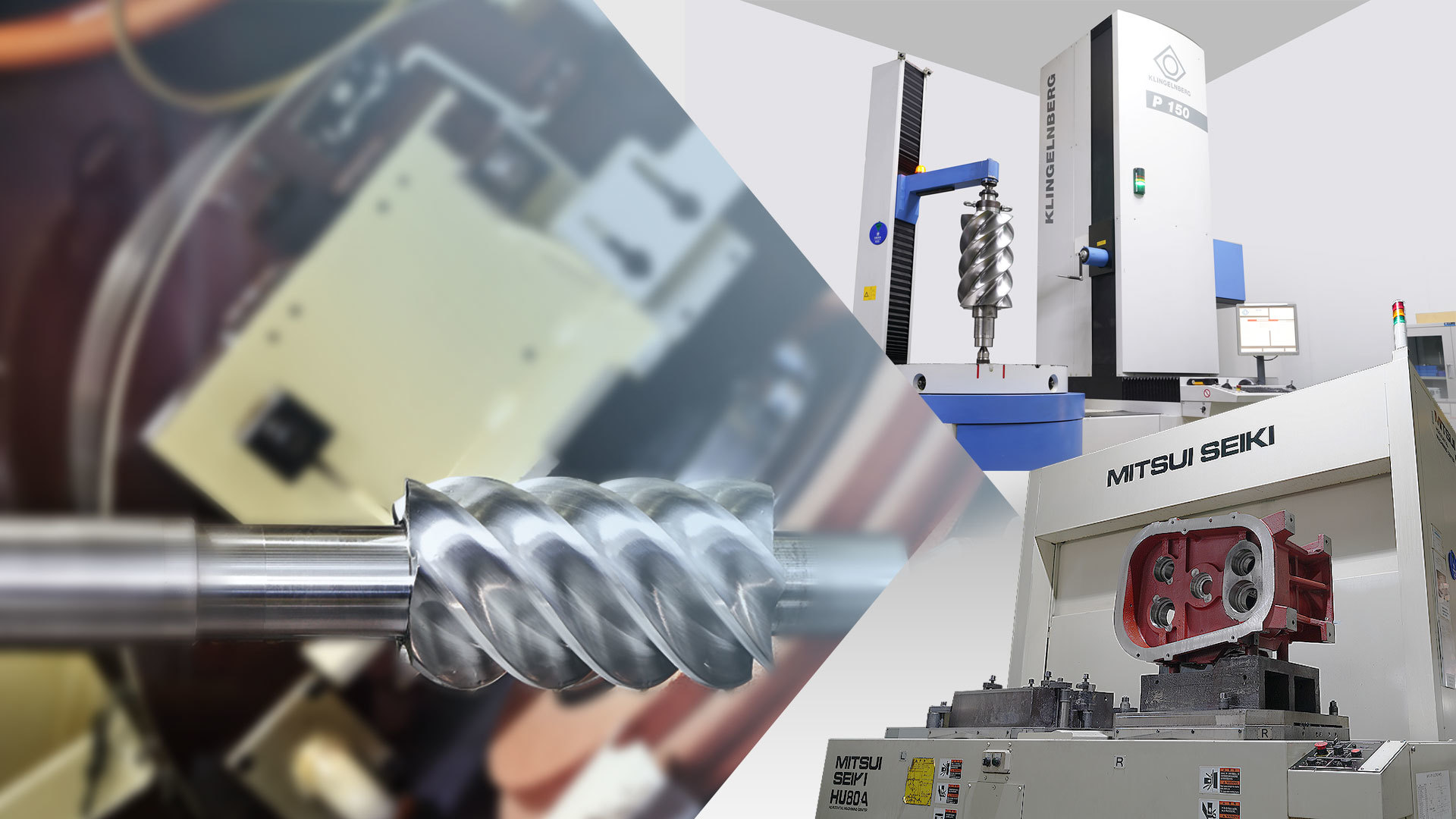

Own INDEPENDENT INTELLECTUAL PROPERTY RIGHTS

Screw compressor core technology and manufacturing capabilities with independent intellectual property rights.

查看详情NINGBO XINDA SCREW COMPRESSOR CO., LTD

Constantly exploring the path of EFFICIENT, ENERGY-SAVING, RELIABLE, AND DURABLE

brands.

查看详情NINGBO XINDA SCREW COMPRESSOR CO., LTD

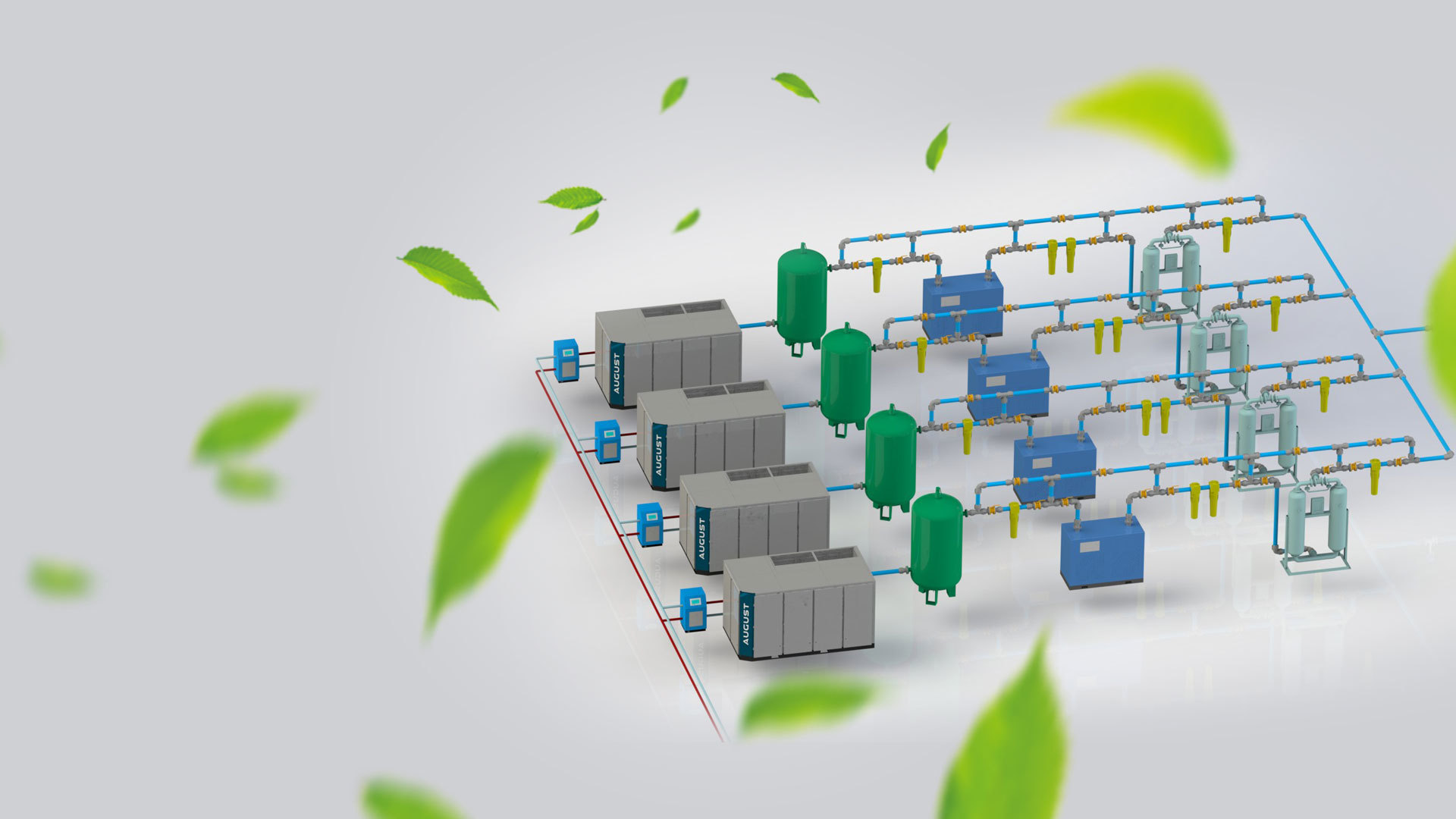

Focus on energy-saving technology research ofHIGH EFFICIENCY AIR COMPRESSOR AND STATIONS.

查看详情ENERGY-SAVING AIR COMPRESSORS FOCUS ON QUALITY&HELP ACHIEVE CARBON NEUTRALITY.

OUR CLIENTS

Products cover various industries throughout China and are exported to multiple countries in Southeast Asia, Africa, the Middle East, South America, Europe, and Oceania.

Ningbo Xinda Screw Compressor Co.,Ltd.

Address: Dongwu Town, Yinzhou District, Ningbo City, ZhejiangProvince, China, Zip/Postal Code: 315113

Tel: 0086-574-88336011

Fax: 0086-574-88336161

©2023 Ningbo Xinda Screw Compressor Co., Ltd.